The utilization of virtual trials and tests for agricultural machines offers numerous advantages and presents an opportunity for process optimization. The agricultural sector has commenced the process of digital transformation, which is fostering the advancement of augmented and virtual reality technologies.

Virtual simulation technology is a useful tool in the design, analysis, and performance evaluation of agricultural machines. With the ability to swiftly compare various scenarios, it is easy to identify the optimal design or operational choices.

Real vs virtual

The benefits that virtual reality tools can bring to the agricultural sector are worth considering.

- Firstly, testing and verifying the design choices of new machines usually involves the use of multiple prototypes, resulting in high production costs and emissions. Field trials also require synchronization with agricultural seasons. Virtual simulation can solve both of these problems.

- Secondly, simulating real conditions and experiencing them in advance allows for optimal machine settings during field operations.

- Lastly, operating in controlled environments significantly increases operator safety. The virtual space eliminates the risk of accidents related to user inexperience and serves as a training tool for new operators and a test for customers.

Not all simulators are created equal

Different levels of precision are required for virtual simulations in agriculture, depending on the specific needs of the simulation environment and the agricultural machine being tested.

Here are three levels of accuracy:

- High precision is ideal for verifying design choices;

- Medium precision is mainly used for real-time simulations;

- Low precision is sufficient for training operators and demonstrating machine functionality to customers.

Virtual design

In order to test components during the design phase, a high level of detail and realism is necessary to ensure that all potential factors that could affect actual use are considered. This level of detail requires advanced simulations that, while taking less time than field tests, cannot be performed in real time. As a result, in these simulations, precision in the calculations is prioritized over the graphical interface.

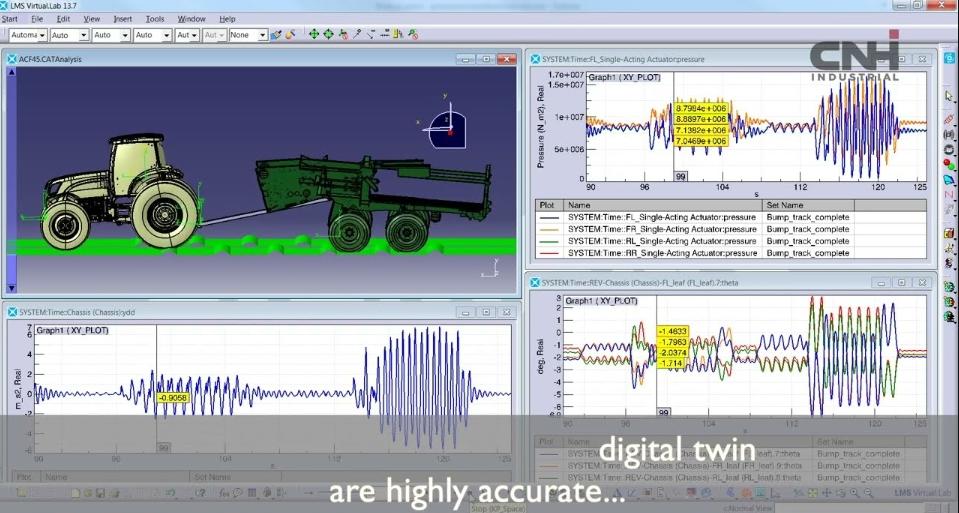

As an example, CNH Industrial conducts “bump tests” during the design phase to monitor vibrations and component responses to external stresses. These tests can provide more information to improve the product if conducted digitally.

Gennaro Monacelli, who is in charge of developing the first dynamic simulator in the agricultural sector of CNH Industrial, explains that the models used for these simulations are called High Fidelity Models, which are very complex and may take several dozen hours, sometimes even up to 24 hours, to run using High Performance Computing (HPC). Thanks to recent advancements in the number of cores (HPC calculation capacity), the entire functioning of a tractor can now be simulated.

Real-time simulations

With the advancements in technology, we now have more immersive forms of simulations such as Digital Twin, which are digital replicas of reality. These simulations are conducted in real time, allowing the operator to experience the functioning of the machine directly through virtual reality (operator-in-the-loop). This architecture typically consists of a central unit responsible for generating and managing virtual reality graphics, as well as an interface with input and output devices for user interaction. This approach helps save time and resources while providing a more realistic experience.

Monacelli explains that to achieve this type of simulation, they transition from High Fidelity models to Real Time ones, which are less complex but operate in real-time and provide accurate results. The model immediately responds to inputs from the user.

The farm is digitised

SimAgri is a real-time simulator for agricultural machinery and is an example of a tool created by the Crea researchers as part of the AgriDigit project, which is financed by the Ministry of Agriculture, Food Sovereignty and Forests.

Carlo Bisaglia, the simulator site manager at Crea di Treviglio, explains that SimAgri, which is a real-time agricultural machinery simulator, is not a video game but a tool consisting of a physical component, i.e., the tractor’s driving position, and a virtual component, i.e., the digital twin of the company and the machine. The most remarkable aspect of the tool, according to Bisaglia, is the ability to generate different scenarios and select the optimal one without the possibility of making mistakes and without having to wait for the following year to perform the experiments again.

The SimAgri simulator was developed specifically to assess and test new precision farming techniques. The aim of the researchers was to create a system that allows farmers to virtually operate a large fleet of machines and test various options according to different scenarios. Currently, the simulator can support a variety of equipment for activities such as seeding, fertilization, and pesticide distribution.

Bisaglia also mentions that SimAgri can serve as a training tool for new employees. With the simulator, they can learn how to operate and manage operations in the field before doing so in real life.

Driver in the loop

CNH Industrial recently unveiled the Dynamic Driver-in-the-loop Simulator in Modena, which tests the performance of every component of a tractor – including mechanical parts and software – before it is manufactured. What sets this simulator apart is that it features an actual cab that can be swapped out and customized to fit any type of tractor, thanks to universal interfaces.

Monacelli explains that the Dynamic Simulator is a crucial component in the product development process at CNH. They are able to simulate the features of new machines with great accuracy, and in addition to numerical simulations, they can physically test the machine for the customer even before production.

Similar to the Crea simulator, the Dynamic Simulator can also simulate operating conditions in the field and various tractor-implement configurations. Furthermore, it has standard digital test tracks that allow the evaluation of different engineering and design solutions.

“The simulator puts the driver in the design cycle (driver-in-the-loop). We can compare two types of suspension and get immediate feedback from different users, including the designer, marketing manager, dealer, and end customer,” adds Monacelli.

Virtual reality for everyone

In order to prioritize speed, graphics, and user experience, simplified simulations aim to approximate reality rather than achieve precise accuracy. This means that instead of a digital twin, we now have virtual worlds that are used not only for operator training and demonstrating machine functionality to customers, but also for simulation games like Giants Software’s popular Farming Simulator.

An example of this is Farming Simulator, which meticulously replicates the agricultural world with a keen focus on graphic details. The farming equipment in the game mimics the appearance of real-life vehicles and even requires maintenance after heavy usage, similar to real-world scenarios.

What sets it apart from previous simulators is the lack of realistic models that can digitally recreate genuine physical phenomena like the interaction between wheels and soil, both in terms of vehicles and the environment.

What awaits us in the future?

Virtual reality and simulations are currently and will continue to play a crucial role in agricultural mechanization. These tools can speed up development processes, cut costs, help select the most suitable machinery and settings for use in the field, and even revolutionize machine approval procedures through virtual testing.

Bisaglia concludes that with SimAgri’s integration of more advanced models, it will be possible to simulate all agricultural operations and provide proactive recommendations on the ideal approach and execution methods. This will have a positive impact on the costs and environmental effects of agriculture.

Monacelli concludes that new virtual technologies are revolutionizing the way products are conceptualized, designed, and manufactured. At CNH, they aim to anticipate and assess potential scenarios and engage customers directly in the design phase to create customized products that address the real needs of farmers.